For 40 years, C. E. Schneckenflügel GmbH in Edewecht, northern Germany, has been a guarantor for the production of high-quality auger blades for screw conveyors. Today, however, customers’ demands go beyond purely solid mechanical production. In the meantime, the focus is at least as much on optimal production processes and workflows as on automation and digitization, in order to obtain the exact screw flights quickly and at low cost. The company therefore opted for the Siemens Opcenter APS software for detailed production planning. The implementation was carried out by the experienced Siemens sales and integration partner A+B Solutions.

Rolf Eiting is an active person. Since he took over the management of the traditional company C. E. Schneckenflügel GmbH a few years ago, he has been constantly pushing the issue of digitization there. For him, it is clear that this is the only right way to ensure the competitiveness and thus the future of the company: “When we were founded 40 years ago, we were shaped by the mechanical and manual production processes used to manufacture our sectional flights. Today, we make sure that the processes are state-of-the-art to offer the best performance at the best price.”

Sales more than doubled

This attitude now permeates all areas. Rolf Eiting recognized that investing in production equipment is only one side of the coin. Only the investment in the associated digitization brings significant increases in productivity and sales. “Five years ago, we started to consistently invest in digitalization. This strategic decision led to us more than doubling sales during this time without significantly increasing our team. Today, we generate 4.5 million euros with 17 employees, whereas back then we employed 14. At the same time, we halved the average delivery time from 14 days to one week. We often even manage to do it in just a few days. On top of that, the error rate has been drastically reduced and material yield increased.”

Central production control

So much efficiency attracts attention. C. E. Schneckenflügel GmbH, for example, received the “Große VR-Mittelstandspreis Weser-Ems” 2020 for exemplary optimization and digitalization. In the survey of the magazine Focus in cooperation with Statista on the fastest growing German companies in 2020, C. E. Schneckenflügel GmbH made it into the top 100. In the meantime, the production control system in particular has made a significant contribution to the expansion of success. Managing Director Eiting can still remember the beginnings well: “Until a few years ago, we didn’t have any electronic production control at all. The production manager and the sales manager spent 20 minutes a day discussing which orders were pending and what had to go out. Then we started to rebuild our ERP system. The ERP system, infra:NET, offered a module with production control, which I initially had implemented with the primary intention of getting accurate information about production utilization. Unfortunately, the team’s acceptance was low due to the wonky user interface. To be precise, I was the only one using the system on a regular basis. So when I happened to discover Opcenter APS from A+B Solutions at the EMO trade show in Hannover in 2019, I was immediately electrified. We invited A+B Solutions to us in Edewecht for a presentation and were immediately impressed by the graphical user interface. What kept us from placing an order immediately was the question of the connection to the existing ERP system infra:NET.”

New ERP partnership

At that time, the ERP software manufacturer, iN|ES GmbH in Calw, was itself looking for a replacement for the previous module for production control. This had been created by a small system house whose owner retired and discontinued further development. For iN|ES GmbH, there were now plans to program its own solution or to fall back on that of an existing provider. On the recommendation of Rolf Eiting, an exchange between iN|ES and A+B took place. A+B Solutions GmbH specializes in digital solutions in the manufacturing sector and can itself look back on 40 years of experience. Especially in the Siemens environment, the company is well established as a Siemens development and sales partner. Since the Opcenter APS (Advanced Planning and Scheduling) program from Siemens is offered and distributed worldwide in the “Industries Software” sector, this represents a considerable safety factor for iN|ES GmbH in terms of consistency and future security. Consequently, nothing stood in the way of a cooperation and integration partnership with A+B Solutions GmbH, especially since both have a similar company size with a similar customer structure, which benefits from the combination of ERP and production control.

Successful incorporation

The first beneficiary of the cooperation is C. E. Schneckenflügel GmbH with Managing Director Rolf Eiting. As the initiator, he now benefits from the pilot role: “After the cooperation was established, we introduced Opcenter APS directly and immediately had very good experiences. After five days of training and familiarization by A+B Solutions, we were already able to work with the system. Our production manager is also convinced and uses the software for production planning intensively.” The next step is to link the system to Reiner SCT’s existing personnel time recording system. Master data of machines and personnel are required for comprehensive capacity planning. With the coupling to the personnel time recording system, the data exchange is then automated.

Red thread automation

The automation aspect is of central importance to Rolf Eiting. It runs like a thread through the entire company: “If there is an opportunity to automate a work step, we take it. Currently, there is no manual input except for order data. No one at our company is involved in permanent data maintenance. Even shipping and handover to the freight forwarder is done automatically. All the necessary information flows from the systems, such as ERP, into the production control system. The production control system supplies the plasma cutting system with order data and shows when the order can be produced on which press. It takes over the automatic generation of the production plans and the work schedules, as well as the transfer to the sheet cutting system, where the optimal nesting is carried out independently. The production control system indicates when the cutting can take place at the latest. If the nesting plan is not optimal, it is cancelled and the system waits to see if another order with the same sheet thickness comes in. This saves material because there is less waste. The entire work process is fully automatic and we always have an up-to-date status. In the second work step, the cut rings are pressed into screw flights. Based on the data from the production control system, the orders are distributed to the presses.”

Short lead times

The time span between order and delivery is relatively short at C. E. Schneckenflügel GmbH. The screw flights are cut from sheet metal as rings and then pressed into shape. The customer selects the desired sheet type and thickness as well as his parameters for the screw flights from a stock capacity of 400 tons. The entire production process is exclusively order-related, i.e. production only starts when an order is received. As soon as an inquiry is received, the interested party receives a quotation within 24 hours. Once the order has been received, a binding delivery commitment is issued within five to ten days, irrespective of standard or special design. If it has to be faster, the express option takes effect. This fast turnaround requires precise detailed production planning.

Binding delivery time statement

C. E. Schneckenflügel GmbH has a broad customer base of about 2500 active customers. Their order frequencies as well as the volume varies greatly and can range from very small orders of 100 euros to several tens of thousands of euros. “Our goal is to make it as easy as possible for customers to place orders and to deliver as quickly as possible with the best quality and a binding delivery promise. If we promise a delivery date, it must be met. With Opcenter APS detailed production planning from A+B Solutions we achieve this goal. This solution is the basis for the high productivity we have achieved today. Opcenter APS developed into the central software in our production,” summarizes Rolf Eiting.

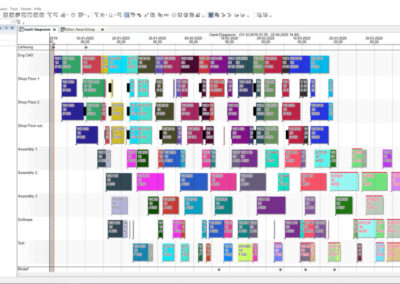

Opcenter Scheduling for detailed planning

The extensive experience of A+B Solutions GmbH helped to adapt Opcenter APS to the manufacturing processes of C. E. Schneckenflügel GmbH. For the special needs of C. E. Schneckenflügel GmbH, to achieve a high degree of automation of the processes with short lead times, the focus is on the module “Opcenter Scheduling”. With it, production processes can be planned particularly well in the long term and controlled in the short term. The licensing distinguishes between “Planners” and “Viewers”. At C. E. Schneckenflügel GmbH, the planners include Rolf Eiting as managing director and the production manager. Viewing licenses are available in the sales department. This means that information on production capacity and order status can only be viewed there. Approximately one hundred orders per week are processed in this way. Each order is divided into five to six operations, resulting in up to 600 operations that are managed weekly by Opcenter APS in Scheduling.