Seamless integration of manufacturing in Teamcenter

Shop Floor Connect (SFC) for Teamcenter

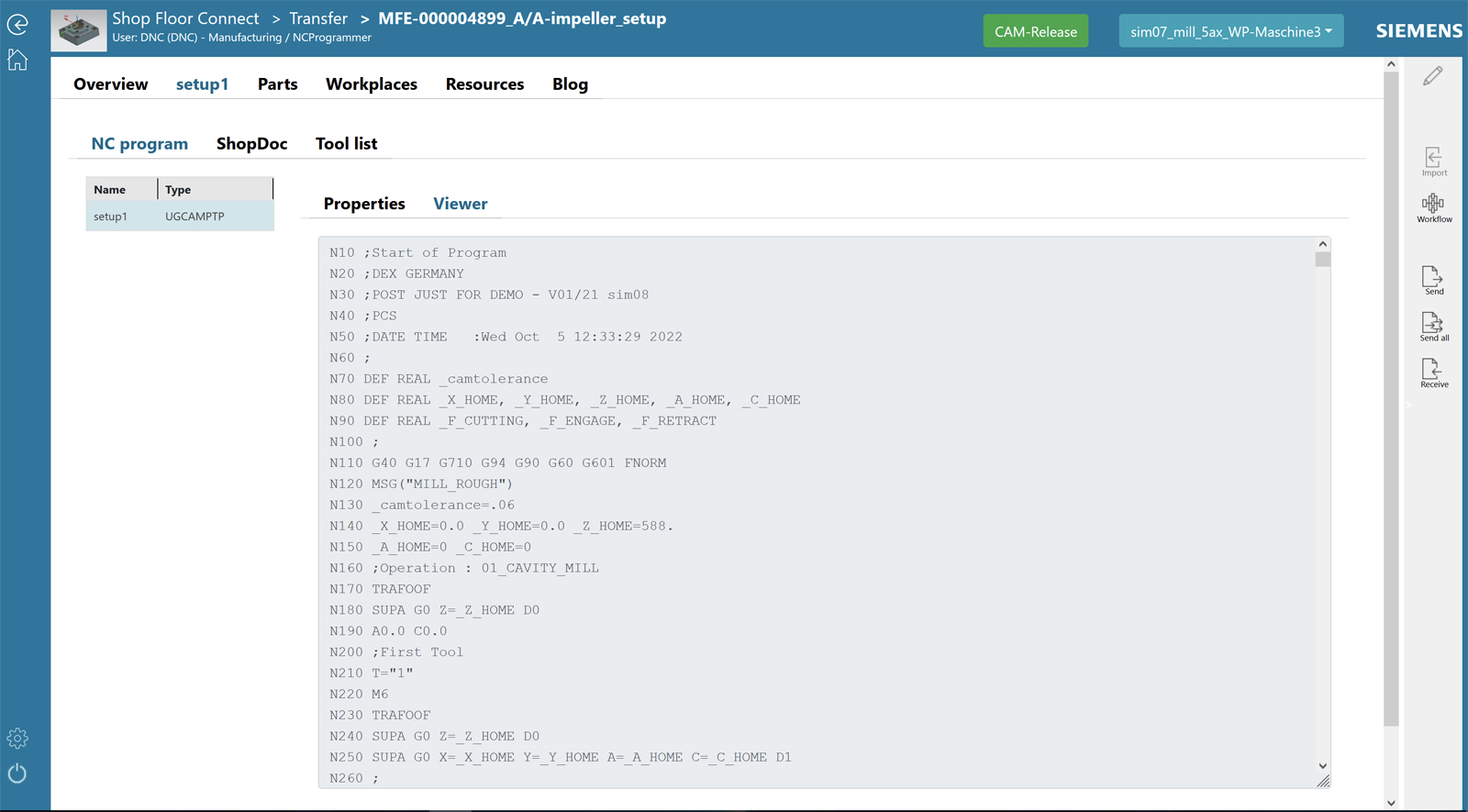

Shop Floor Connect for Teamcenter is the integrated Teamcenter add-on application for transferring NC programs from Teamcenter directly to the machine control. In contrast to traditional DNC systems, the direct connection to the central Teamcenter database avoids duplicate data storage and, through revision management, ensures that only currently released production data is used. It enables production staff to effectively access production-relevant data from Teamcenter via a web-based user interface that can be accessed via a browser.

Connection to Teamcenter

Shop Floor Connect for Teamcenter is an application that communicates directly with the Teamcenter PLM system from Siemens Digital Industries Software. Teamcenter enables comprehensive data and process management of the product lifecycle (PLM) – from concept to development to production.

Teamcenter provides the environment to manage product data, process definitions, data sets and resources. It supports the user with workflows and specific roles and rights in the process chain and enables tracking of document revisions and release status.

Due to the integration of SFC in Teamcenter, no stand-alone manufacturing database is required. Production data is managed in a controlled environment until it is requested by the machine. The machine operator or foreman on the shop floor always has access to the data managed and released by Teamcenter. The data required for manufacturing can be transferred directly to the manufacturing machine, tool presetter, robot, 3D printer or an assembly line.

SFC functions

- Transferring/retransferring NC programs or tool data from a production machine or a tool presetting device

- Storage of machine-programmed NC programs and control settings for backup and management in Teamcenter

- Serial connection of different controls (via additional hardware), via a network or from tool presetter

- Retrieval and display of all released manufacturing information via the web-based user interface: NC programs, tool lists, setup sheets, digital photos, clamping plans, user and assembly instructions, drawings, 3D models, films, tool nominal and actual data, configurable access authorizations for workstations and users (groups, roles, assignment of rights)

- Transfer logging of all data that is transferred or retransferred to the machines

SFC advantages

- Assured use of correct, released data in production

- Reduction of production interruptions

Minimization of downtimes, since the data do not have to be searched for or questioned - Closer link between development and production engineering and manufacturing

- Secured processes and workflows up to and back in production

- No need for independent databases outside the IT infrastructure on the shop floor

- All users have the same view of the data

- Reduction of scrap rate

Basis for paperless manufacturing

Faster and more flexible information flow - Support of compliance requirements through traceability of data transfers

Simple web-based user interface also applicable via touchscreen or on the controller (no local installations necessary) - Closed process chain