Data management and production connection made easy with NX CAM

The challenges for the native user of the 3D NC programming system NX CAM are manifold

- Where and how do I manage my data?

- Is the data transparent for everyone?

- What is the released data?

- What happens to changes from production?

- How can I ensure secure access?

- Can I connect a DNC system?

Especially for users of 3D CAM systems, there is another level of complexity that has to do with the amount of data that has to be generated. One part data set from the design can easily become 1,000+ in CAM. The task is to get a handle on these data volumes.

For this requirement, Siemens Digital Industries Software has created a technology and migration path with different solutions that allow the customer to grow from a native to a fully integrated and managed Teamcenter environment. One solution for this is DNC Connect for NX.

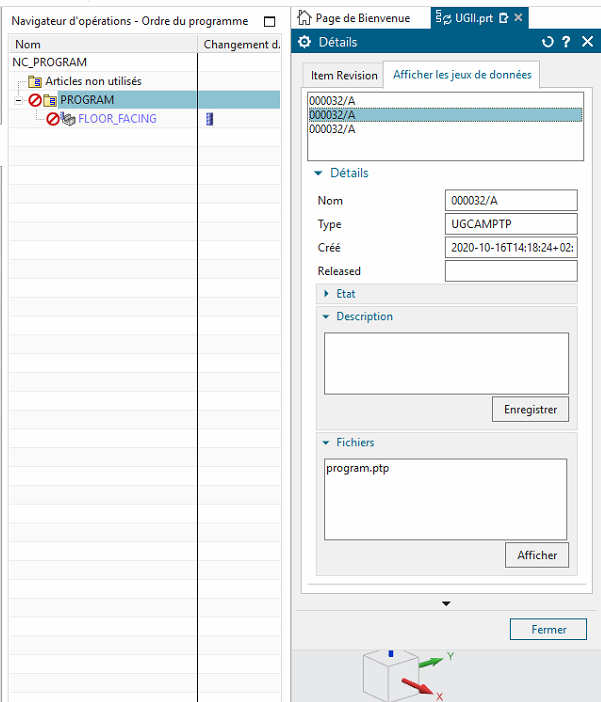

DNC Connect for NX enables native NX CAM users to easily and directly manage their generated manufacturing data such as NC programs, tool lists, setup sheets or fixture plans. With Shop Floor Connect, this data can also be made available to manufacturing. Advantages for the native NX CAM user are an integrated administration and user interface, a quick search of his stored information in NX CAM and the secure administration of his data in a uniform environment.

In addition to management, DNC Connect allows the NX CAM user to create, search, revise, release and also lock manufacturing data. The user can do all this directly from the familiar NX CAM interface without having to leave it. If the NX CAM user also uses the MRL Connect tool management system from Siemens Digital Industries Software, the tools used in the CAM module are also referenced via DNC Connect. Through the coupling with the Shop Floor Connect Machine Tool Clients (machine connection and worker interface), the production data managed in DNC Connect can be viewed directly by the worker at the machine and NC programs can be transferred to the machine and optimized transferred back from the machine.

The benefits

- Fast learning curve due to integration into the NX CAM user interface

- Central revision- and access-proof management of all files generated by the postprocessor from NX CAM

- Reference of used resources like machines and tools (with MRL Connect)

- Continuous process chain from NC programming to the machine and back in combination with Shop Floor Connect

- Tracking of changes from the shop floor