The scalable web-based MES/production information system for total transparency in production

FIT-WebMES is the answer to the questions that companies involved in discrete parts manufacturing must ask themselves

- How can I become or remain competitive?

- How can I get my products to the market faster?

- How can I optimize my processes?

- How can I shorten my throughput times?

- How can I increase transparency?

- How can I improve quality?

- How can I improve my delivery reliability?

- How can I keep or bring my costs under control?

- and many more

FIT-WebMES combines the information from the technical level (CAD/CAM/PLM) with that from the commercial world (PPS/ERP) in a single solution with an interface for workplaces, machines and operators in production.

Thanks to its scalability, FIT-WebMES offers the possibility of beginning with operating data collection and then, step by step, building a comprehensive MES solution with production control (FIT-CapaTool), machine data collection including alarms (FIT-WebMDE), the DNC extension FIT-WebDNC as well as the key figure solution FIT-AnalyseTool. It is supported by FIT-Additional Modules, with which you can connect ERP systems (FIT-ERPConnect) and automatically store data from the CAM system (FIT-CAMIntegrator) or obtain an online overview of the workplaces in production (FIT-HI-WebMenu-InfoCenter).

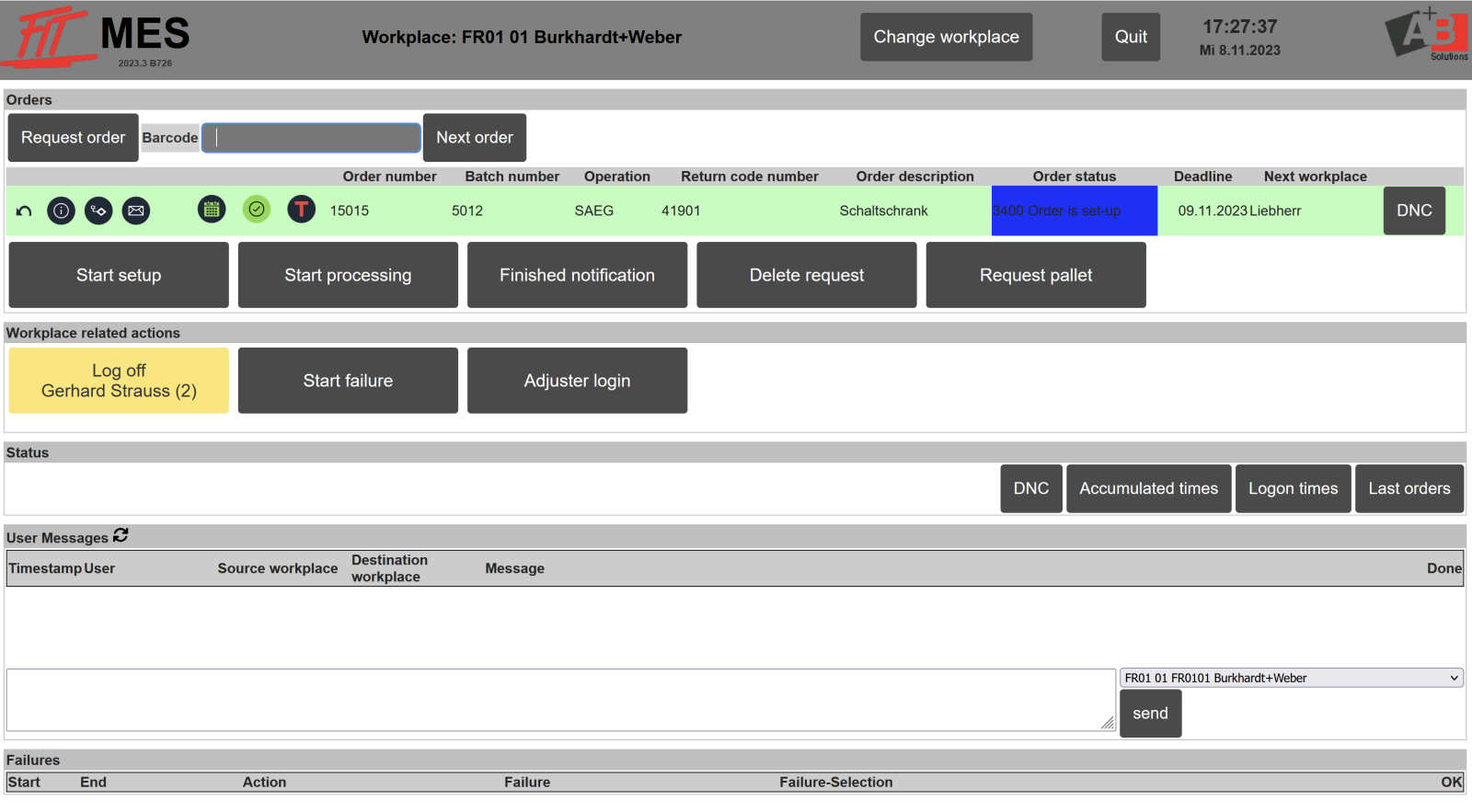

The operator in production has one user interface optimised for his area of work via which he can access and visualise the relevant order and part information and report activities and information about the individual work processes for the production orders. This simplifies thing for the production worker since he no longer needs to interact with different user interfaces and can focus on what’s important.

Thanks to state-of-the-art development technologies, the user interface is completely independent from the operating system and the hardware. This means that FIT WebMES can be operated using standard PCs, IPCs (Industry PC), panel PCs, tablets or smartphones. The sole requirement is a browser on the device. This solution offers the basis for low-paper productions.

Like all solutions, FIT WebMES is based on a database (Microsoft SQL Server or Oracle) to professionally manage data and information. The available standard interface to connect to external CAM systems allows the data and information created there to be stored automatically.

FIT-WebMES consists of the following software modules

- FIT-Base-Software

- FIT-Workplace Management

- FIT-Order Data Management

- FIT-Time Data Management

- FIT-ERPConnect

- FIT-HI-WebMenu

- FIT-HI-WebMenu-InfoCenter

- FIT-HI-MES

Optionally expandable using the following modules

-

- FIT-Personnel Data Management

- FIT-CapaTool

- FIT-WebDNC

- FIT-WebMDE

- FIT-AnalyseTool

FIT-WebMES connects worlds

- Transparency thanks to current online information and production conditions

- Reduction of throughput times thanks to the combination of all necessary information – exactly where you need it

- Transparent potential for optimisation thanks to key figure-based weak point analysis

- Increased delivery reliability thanks to the optimisation of the sequence of operations for production orders

- Transparent cost information for product costing analysis and optimisation

This means increased quality, productivity and competitiveness.

FIT-WebDNC

FIT-WebDNC is a web-based solution for the integration of various machine control and interface combinations (Ethernet, serial or protocol-based). Using the production information stored in FIT-Parts Data Management such as NC programmes, tooling sheets, clamping plans, tool lists, drawings or 3D, any authorised employee from work preparation, production or assembly can view the data using the browser-based FIT-HI user interface.

FIT-WebMDE

This solution allows machine data to be collected in various ways in order to free the operator from doing so manually and to obtain precise values for clear workplace assessment. FIT-WebMDC can be used for the workplace-based (machine data collection) or, as a supplement to FIT-WebMES, order-based collection (operating data collection) of data.

FIT-CapaTool

The FIT-CapaTool module provides the possibility for detailed manufacturing control and planning of the manufacturing orders based on capacities and resources (manpower/machines/workplaces). By using an electronic planning board, the current utilisation and planning of the manufacturing orders as well as the personnel situation can be visualised and rescheduling undertaken.

FIT-AnalyseTool

The FIT-AnalyseTool uses the plant and machine data acquired in FIT and analyses and visualises it based on key figures on the foundation of VDI 3423. This is the basis for permanent production controlling.