Data-driven optimizations for more efficient and precise manufacturing processes

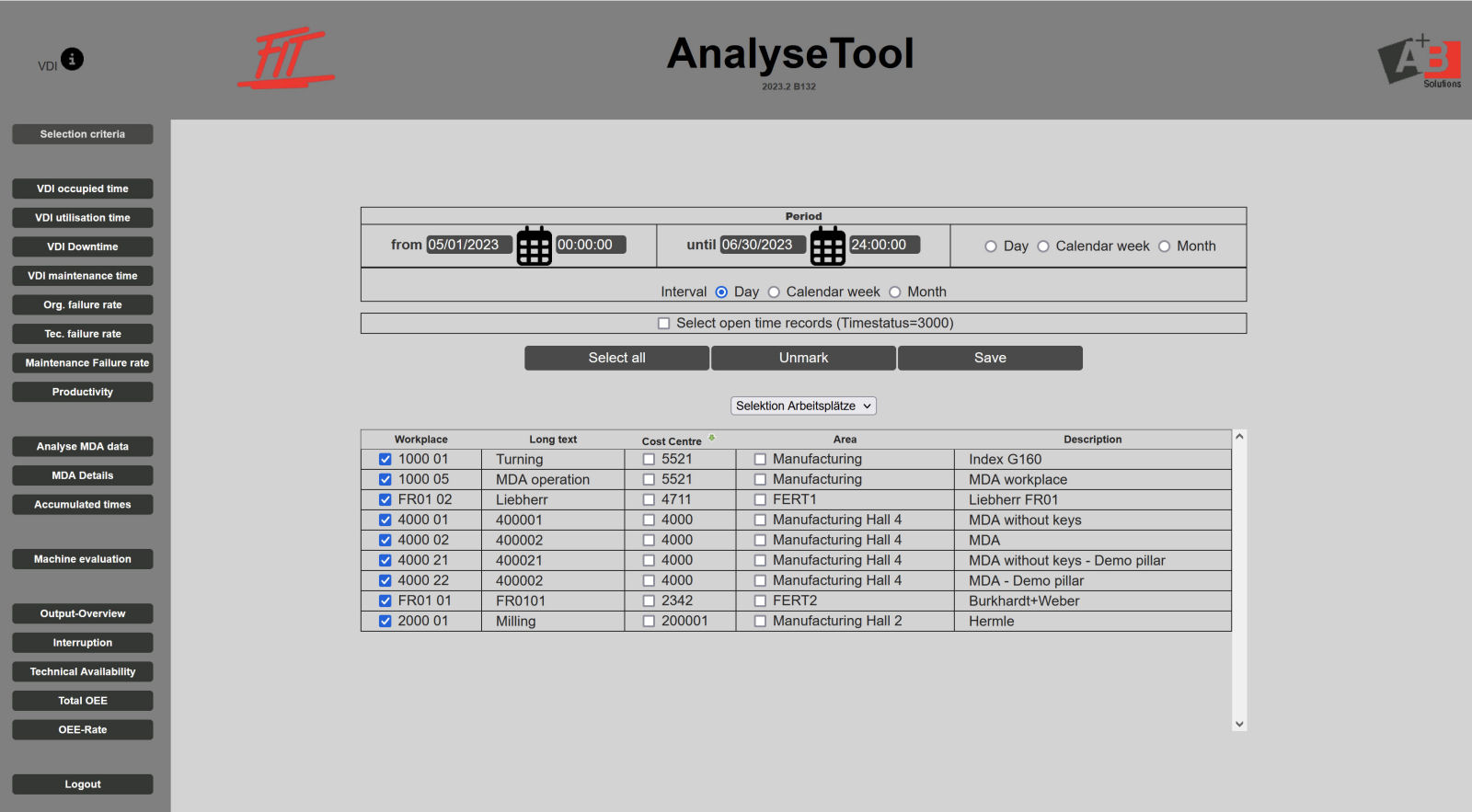

FIT-AnalyseTool

Production Controlling based on key figures

The permanent availability of systems and machines is one of the key factors for companies in the manufacturing industry to hold their own in national and international competition, as the cost, quality and delivery reliability factors depend on this.

Only collection and analysis of process, machine and malfunction data will reveal where weaknesses exists and how they can be eliminated, or the capacity to predict where possible malfunctions and stoppages are developing.

FIT, the factory integrating tool, provides a foundation for this in order to setup a comprehensive solution for production control with the possibilities of plant (FIT-WebMES) and machine data acquisition (FIT-WebMDE).

The FIT-AnalyseTool uses the plant and machine data acquired in FIT and analyses and visualises it based on key figures on the foundation of VDI 3423. This is the basis for permanent production controlling.

The FIT-AnalyseTool uses the plant and machine data acquired in FIT and analyses and visualises it based on VDI Guideline 3423. This forms the basis for permanent production controlling based on key figures.

What’s more, OEE assessment is of course also possible. The objective here is to be able to recognise losses in the value creation chain and rectify them immediately.

The FIT-AnalyseTool is also a useful and necessary extension to FIT-WebMDE and FIT-WebMES solutions, which utilises the data recorded and administered there.

Advantages of the FIT-AnalyseTool include:

- Standardised reports are available throughout the company

- Basis for analysing weaknesses

- Basis for reviewing optimisation efforts

- Increased productivity

- Increased machine availability