FIT-Server-Software (Factory Integrating Tool)

FIT as a comprehensive production information and MES solution

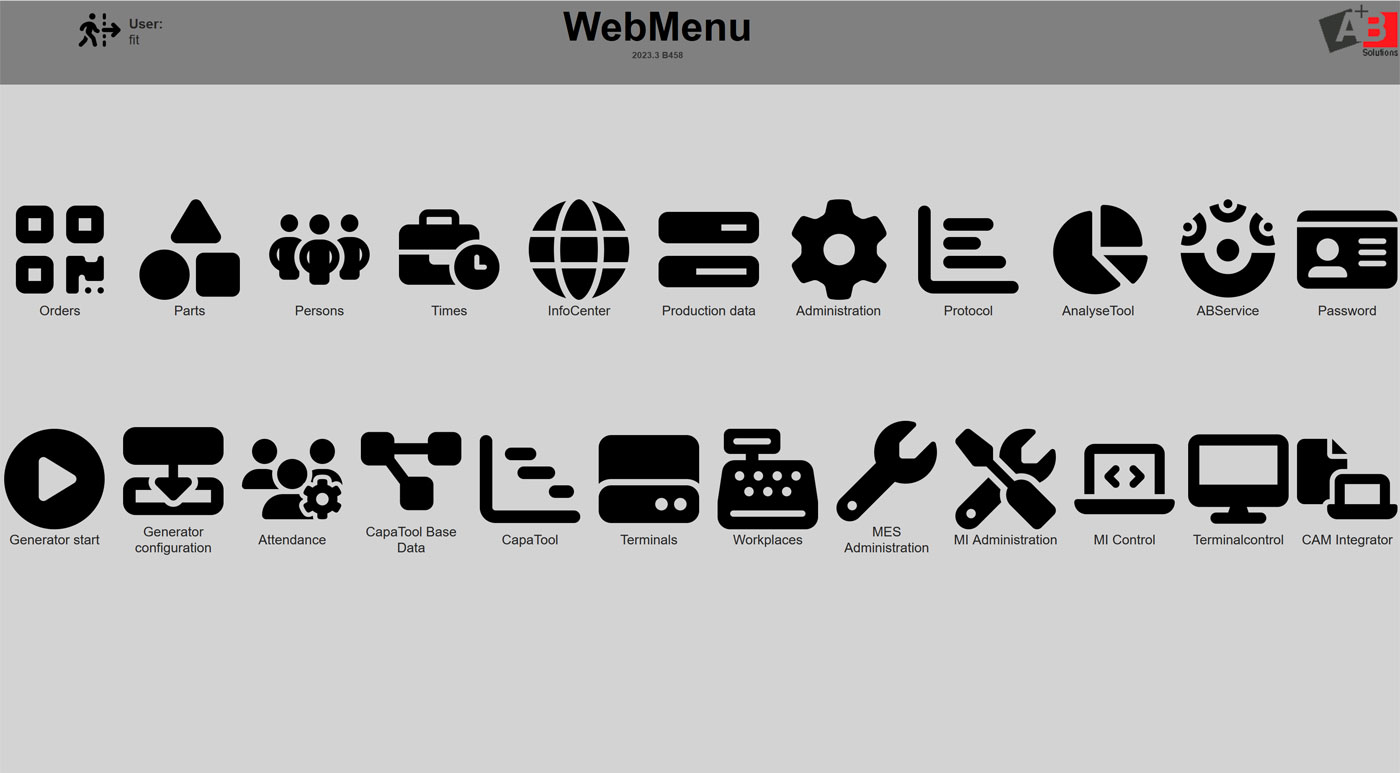

The core modules of the FIT server software form the basis of the scalable FIT (Factory Integrating Tool) production information and MES system. The modules can be individually selected to meet the client’s requirements.

FIT therefore always offers a fitting solution for increased transparency and greater productivity.

- Administration of production data

- DNC transfer of NC programmes and tool data to the machinery

- Collection of machinery data

- Reporting of activity and statuses of production orders via factory data capture

- Fine-tuning production

- Key figure-based analyses

FIT-Base-Software

The FIT base software is the basic module on which the individual server modules build and with which all data and information are administered and organised in Microsoft SQL Server or Oracle databases. The central component of the FIT base software is a unified user administration via which groups and rights can be configured and related workplaces can be controlled. The administration tools also include licence monitoring and logging of user activities.

FIT-Workplace Management

The FIT Workplace Management module manages all connected workplaces such as NC machines and manual workplaces as well as tool pre-setting and the relevant configuration. A cost centre or shift models assigned to a workplace are integrated into the workplace management.

The “FIT-HI-WebMenu-InfoCenter” (browser-based platform for all information stored in FIT) is available as an additional module and graphically represents the current workplace statuses as a list or hall layout.

FIT-Parts Data Management

The FIT-Parts Data Management manages all production data and information relating to a particular part. These may be NC programmes, tooling sheets, tool lists, clamping plans or, for example, drawings. It can be used to manage modifications fed back from the NC machinery or the subsequent attachment of digital photos from clamping situations to a part data set. If necessary, version management can also be activated.

The information from the FIT-Parts Data Management can be visualised using the “FIT-HI” additional module. A comprehensive solution for DNC operations consists of the FIT-Base-Software as well as the FIT-Parts Data Management and FIT-Workplace Management modules.

The”FIT-CAMIntegrator” module links various CAM systems to FIT-Parts Data Management via standard interfaces.

FIT-Order Data Management

FIT-Order Data Management serves to manage production orders which were submitted and approved by an ERP/PPS system in work plans as individual work steps. Work preparation can obtain an overview of current orders and their statuses via the “FIT-HI” additional module, which also gives operators access to the relevant order data for workplace in production.

The collection of operating data requires the FIT-Order Data Management, FIT-Workplace Data and FIT-Time Data modules in addition to the FIT-Base-Software.

“FIT-ERPConnect” is another core module that integrates ERP and PPS systems into FIT-Order Data Management via various interfaces.

FIT-Time Data Management

The FIT-Time Data Management module manages all order and workplace-relevant time units of activities and machine data. The allocation can be based on the order, workplace or individual.

The collection of machine data requires the FIT-Workplace Management and FIT-Time Data Management modules in addition to the FIT-Base-Software.

FIT-Personnel Data Management

FIT-Personnel Data Management stores an excerpt from the personnel master data such as personnel and ID numbers or employee photos.

Using FIT-Time Data Management and FIT-Order Data Management, the personnel data is allocated to the order and time data.

FIT-ERPConnect

ERP/PPS interface for the bidirectional exchange of order data/information based on database exchange tables or other available routines.