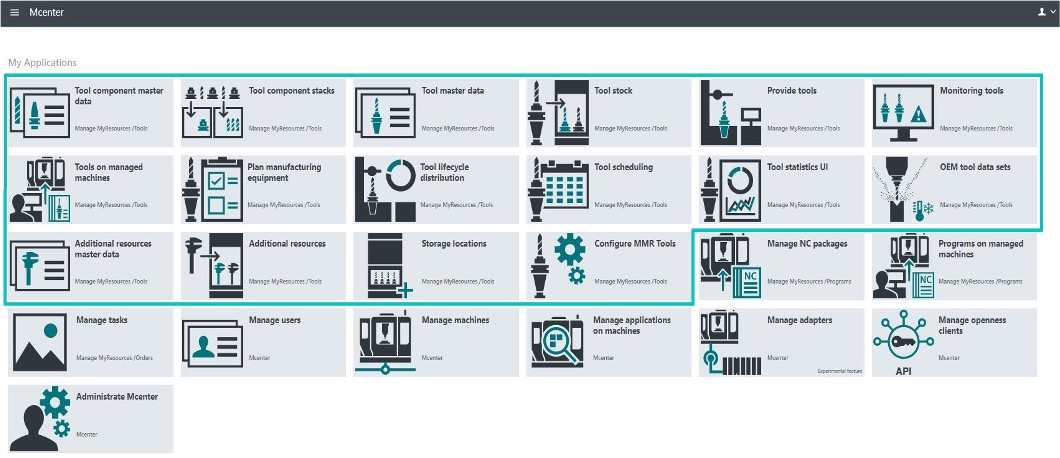

The enterprise shopfloor platform in a nutshell

About Siemens Mcenter Manage MyResources / Tools

Siemens Digital Industries is a global leader in CNC Shopfloor Management Software. Mcenter Manage MyResources / Tools , previously known as Shop Floor Integrate, is a software application within Siemens’ leading Mcenter Integrate for Production suite designed for shop floor management, optimization and digitalization. Manage MyResources / Tools is a tool management software that enables machining and manufacturing enterprises to track and control the complete lifecycle of physical resources on the shop floor. Manage MyResources / Tools acts as the bridge connecting virtual tooling instances used by the manufacturing planning department with the physical tooling instances on the production floor.

Mcenter Manage MyResources / Tools for Physical Tool Management

Manage MyResources / Tools creates physical tooling instances by pulling virtual tool data, such as required components and measurements, from the central Manufacturing Resource Library (MRL) within Siemens Teamcenter Manufacturing, and then makes this data easily available to operators on the shop floor. Once the tool assembly is built, Manage MyResources / Tools can integrate with a presetter to retrieve the actual tool measurements and store this data alongside the tool record in the central database. Manage MyResources / Tools also manages the tooling inventory in a shop, the planning of the number of additional tools that would need to be created to complete a job, as well as the loading and unloading of tools to machines. The system automatically synchronizes with Teamcenter, thus bridging the virtual and physical worlds of manufacturing, maximizing tool life and ensuring efficiency and quality across all your shop floor processes.

So, how does it work?

- A Computer-Aided Manufacturing (CAM) engineer designs the virtual tool in Siemens NX, then defines the virtual tool within Siemens Teamcenter’s Manufacturing Resource Library (MRL) application.

- The CAM engineer then pulls the tool data from Teamcenter MRL and uses it to generate the NC (Numerical Control) machining program within NX. The virtual tool in Teamcenter MRL is linked to all the machining operations for which that particular tool assembly is/was/will be utilized.

- When a tool request is sent to the shop floor tool manager, the tool manager uses the virtual tool definition stored in Teamcenter MRL to create a physical tool assembly on the shop floor. The tool manager then presets the physical tool assembly with a tool presetter.

- The physical tool, along with the measured data, is “stored” in the Manage MyResources / Tools application, and is ready to be used in production. The physical tool with the actual measurements is then sent to the relevant CNC (Computer Numerical Control) machine and loaded for production execution.

By digitalizing and connecting the entire Tool & Resource Management process, manufacturers enable their users to understand what tools are available and to efficiently determine which operations are affected when a physical tool is out of stock or when a component used in a tool assembly is discontinued. Engineers can run a quick analysis within Teamcenter to determine which machining operations would be affected when the tool is out of stock or being replaced by a new tool. As a result, they are able to preemptively update related NC programs as needed, preventing costly interruptions in production. By increasing visibility into existing inventory within the production facility and ensuring that they are only purchasing tools that are not currently on hand, Manage MyResources / Tools also enables manufacturers to reduce their tool inventory and the high costs associated with it.

Features of Siemens Mcenter Manage MyResources / Tools

- Link virtual tool instances in the Siemens Teamcenter Manufacturing database to physical tool instances in the plant

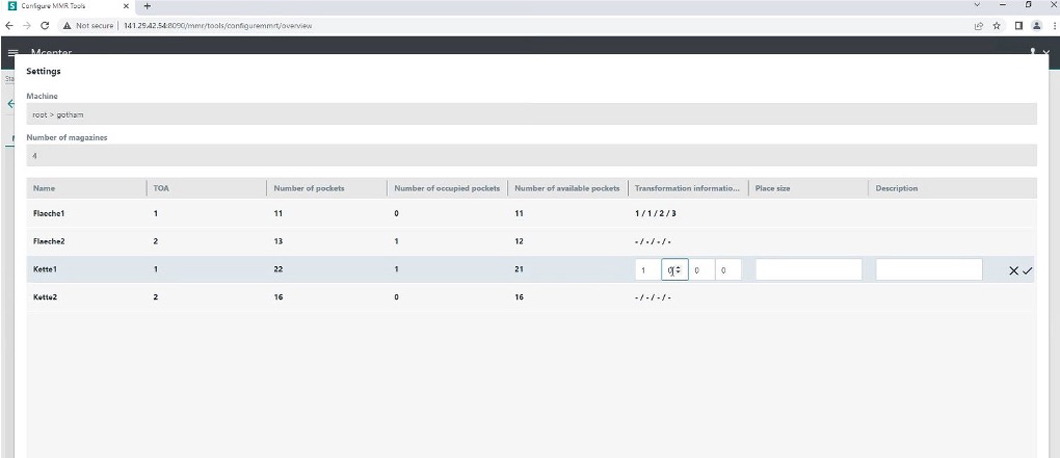

- Track and manage the location of physical tools on the shop floor

Manage tool life and usage history

Search for tools, view tool status (e.g., reservations), and access tooling target data - Provide tooling setup sheets that include the bill of materials for all components required to build a tooling assembly

- View and add additional tooling inventory

- Configure minimum inventory levels and low tooling inventory notifications

- Create or import tooling requirements schedules from the Siemens

- Teamcenter Manufacturing database to understand which tools are needed for a specific job and to determine the usage time for each tool

- Create or link operations to the tooling plan, specifying the machine(s) and number of production runs required

- Balancing to determine the number of tools required for the selected operation(s)

- Interface with the tool presetter

Manage tool presetting data and transfer to NC machines - Interface to Siemens Teamcenter Manufacturing Resource Library (MRL)

Advantages of Siemens Mcenter Manage MyResources / Tools

- Increased tool transparency on the shop floor throughout the production process

- Reduction of physical tool inventory and costs

- Minimization of tool bottlenecks and machine downtime

- Maximize tool life

- Create a single source of tooling data across the enterprise

- Increase manufacturing and data management efficiencies

- Improve the quality of tooling data

- Facilitate change management and collaboration